Design and Optimisation of Two-Phase Vertical Risers in Refrigeration Systems

– Assessing Pressure Drop Impact on COP and the Use of the Kutateladze Criterion

Written by Jonas Sønder Nielsen, Jacob Østergaard and Adam Mark Berman · 21. May 2025

Why Read This Article?

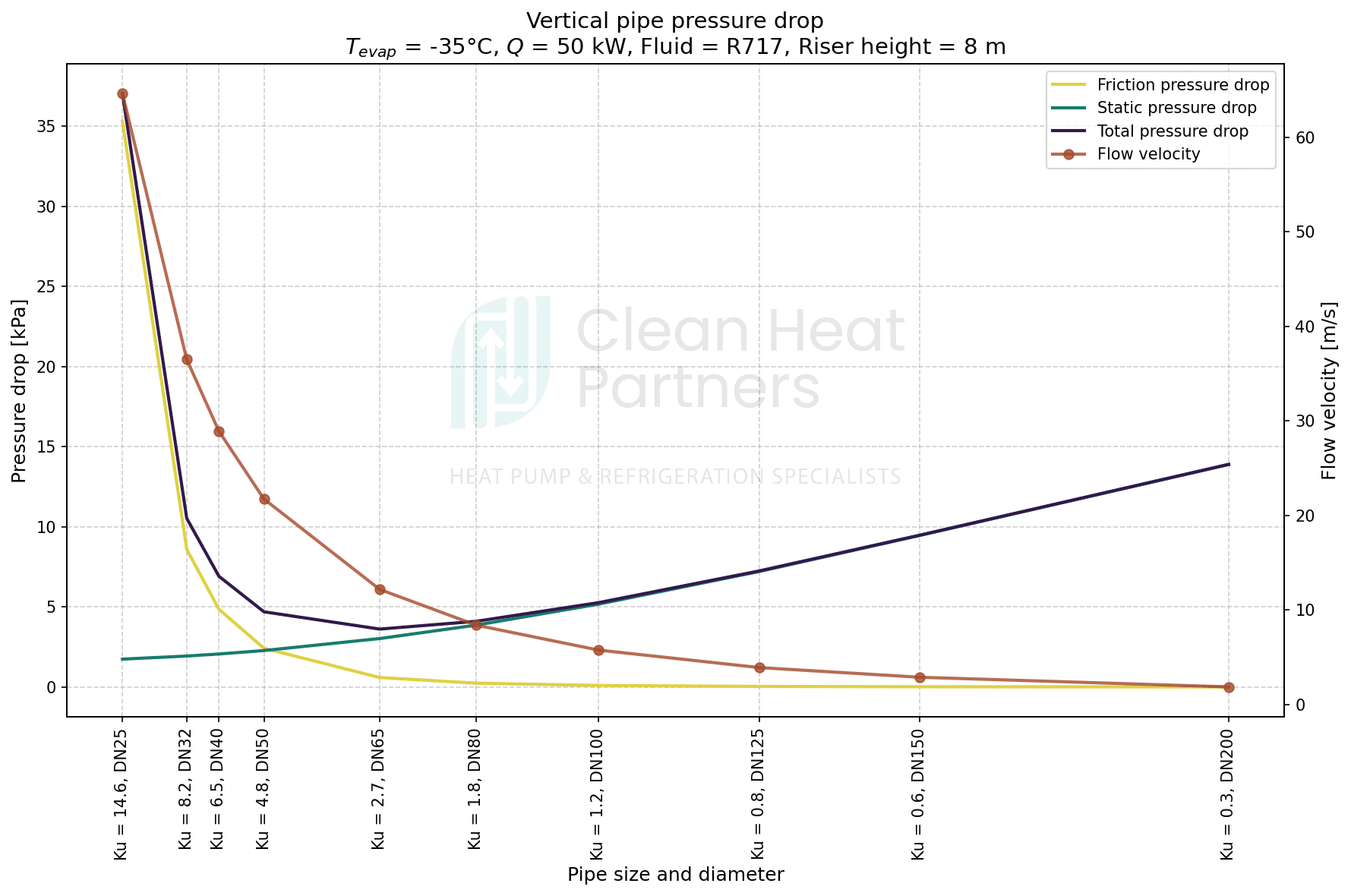

In refrigeration systems with vertical risers operating in two-phase flow, pressure drops can significantly affect the system’s coefficient of performance (COP). These losses—both dynamic and frictional—reduce evaporator performance and compressor efficiency. This article presents a simulation-based analysis of vertical-riser behaviour with special emphasis on pressure-loss mechanisms and design criteria derived from the Kutateladze number. The aim is to demonstrate how proper riser design ensures reliable fluid transport while minimising performance losses.

Introduction

Two-phase vertical risers are critical components in many industrial refrigeration systems, particularly those employing flooded evaporators or thermosiphon circulation. These risers transport a mixture of liquid and vapour refrigerant upward from the evaporator to the separator. However, the combined effects of elevation head, frictional losses and phase interaction can lead to substantial pressure drops, reducing system efficiency and lowering the COP.

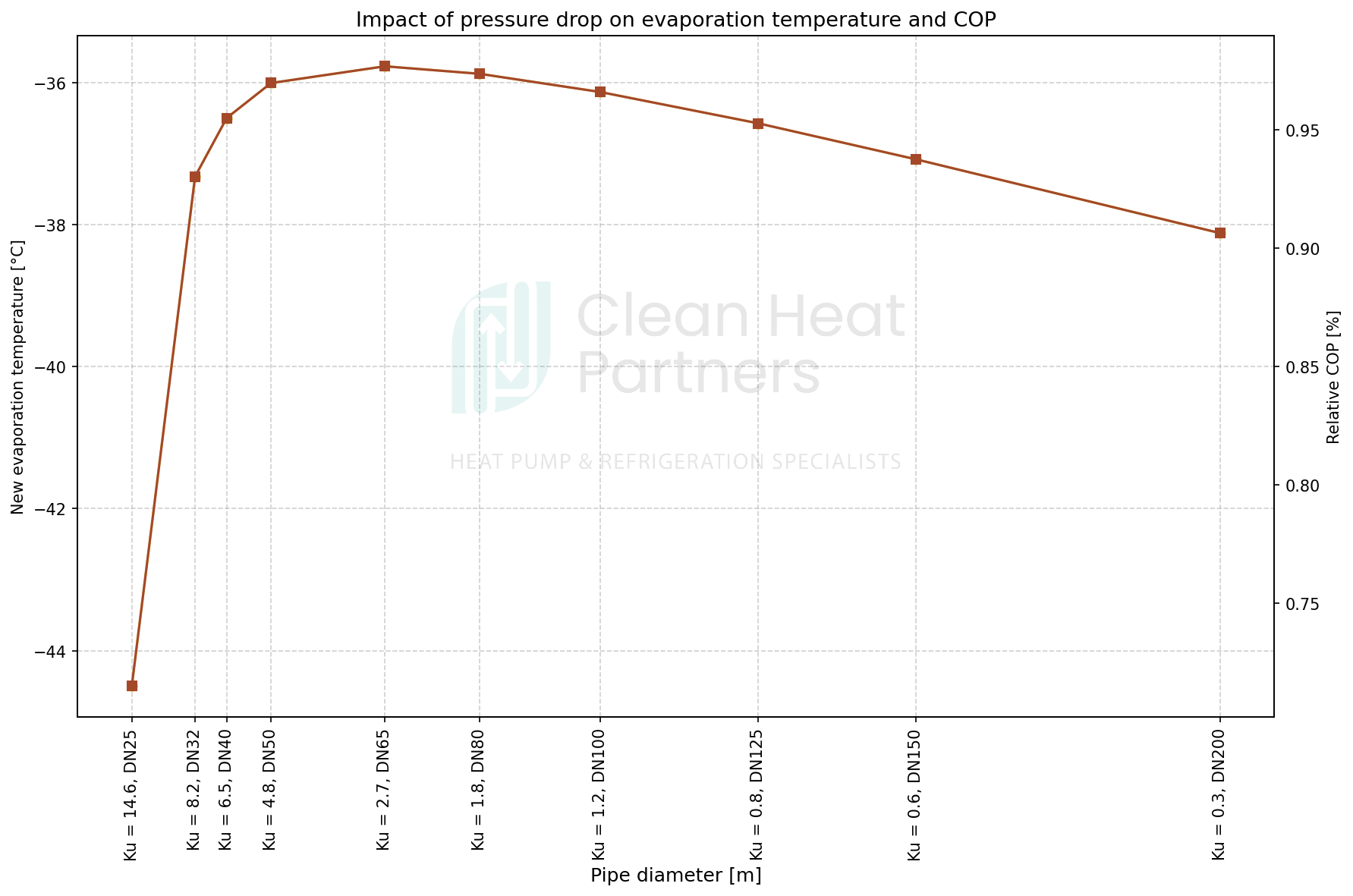

When the pressure drop in the riser is excessive, the evaporator must operate at a lower saturation pressure to compensate. This increases the pressure ratio across the compressor, resulting in greater compressor work and a direct reduction in the system’s COP.

This article explores how pressure losses in vertical risers can be quantified and minimised through careful design. Simulations are used to evaluate the relationship between riser diameter, pressure drop and the resulting COP, while the Kutateladze number (Ku) is applied as a design criterion to avoid flow separation and to ensure satisfactory two-phase transport.

System Configuration and Methodology

- Refrigerant: Ammonia (R-717)

- Vertical riser height: 8 metres

- Mass flow rate: Based on 50 kW evaporator load and -35°C evaporation temperature

- Circulation rate: 3

- Reduction in COP per kelvin decrease in evaporation temperature: 3%

Two key forms of pressure loss are analysed

1. Static head (gravitational pressure drop)

where ρm is the mixture density, g is gravitational acceleration and h is the riser height.

2. Frictional and acceleration losses (dynamic pressure drop)

where f is the friction factor, L is the riser length, D is the pipe diameter and u is the mixture velocity.

Total pressure drop

Design Approach: Kutateladze Number

The Kutateladze number is a dimensionless criterion often used to characterize two-phase upward flow. It is defined as:

where u is the superficial velocity of the vapour phase, σ is surface tension, ρl and ρv are liquid and vapour density

For reliable, non-slug, upward two-phase flow, Ku should typically exceed 3.2. Below this threshold, instability, entrainment, and liquid fallback may occur, all of which increase pressure drop and impair heat transfer.

Simulation Results

Key Findings

- Pressure drops in two-phase risers directly affect evaporator saturation pressure, and thus COP..

- Frictional losses are strongly dependent on velocity, making pipe diameter a critical design parameter.

- Using the Kutateladze number > 3.2 as a design criterion yields an optimum pipe diameter close to that which minimises the overall pressure drop.

- Even small increases in pipe diameter can yield non-linear gains in efficiency due to reduction in dynamic losses.

Conclusion

Two-phase vertical risers are often overlooked in the design of refrigeration systems, yet their impact on system performance can be substantial. This article shows that by properly accounting for both static and dynamic pressure drops or by using design criteria like the Kutateladze number, engineers can significantly improve system COP and ensure long-term operational stability.

Contact Clean Heat Partners at contact@cleanheatpartners.com.