The Impact of Foresight on Heat Pump Optimisation in District Heating

– Evaluating the Role of Spot Price, Load, and Weather Foresight Horizons in Operational Planning

Written by Jonas Sønder Nielsen, Adam Mark Berman and Jacob Østergaard· 21. May 2025

Why Read This Article?

District‑heating operators are under pressure to cut emissions while keeping heat affordable. As large‑scale heat pumps become central to this strategy, the way these units are controlled—particularly with regard to electricity prices and weather forecasts—can have a profound impact on operating costs. This article explores how forecast data, specifically spot prices, heat demand and ambient temperature, influence optimisation outcomes. Using full‑year simulations in CleanDesign, we compare four strategies: a baseline control with no foresight, and rolling optimisations with 1‑, 3‑ and 7‑day forecast windows. The results show that even modest improvements in foresight can yield substantial cost reductions and smarter use of thermal storage.

Introduction

Electrifying heat production introduces new challenges. Unlike traditional boilers, heat pumps are sensitive to external factors such as electricity‑market fluctuations and weather conditions. Their efficiency depends heavily on the ambient temperature, and their operating cost follows volatile electricity spot prices.

To mitigate this, many district‑heating systems use thermal‑storage tanks that allow heat production to be decoupled from demand. However, unlocking this flexibility requires control strategies that can look ahead, using forecasts to plan when to produce and store heat.

This article investigates the effect of different forecast horizons on system performance. Specifically, we examine how access to short‑ and mid‑term forecasts of electricity spot prices, heat demand and outdoor temperature affects operating cost, energy efficiency and peak electricity load in a heat‑pump‑based system.

Simulation and Method

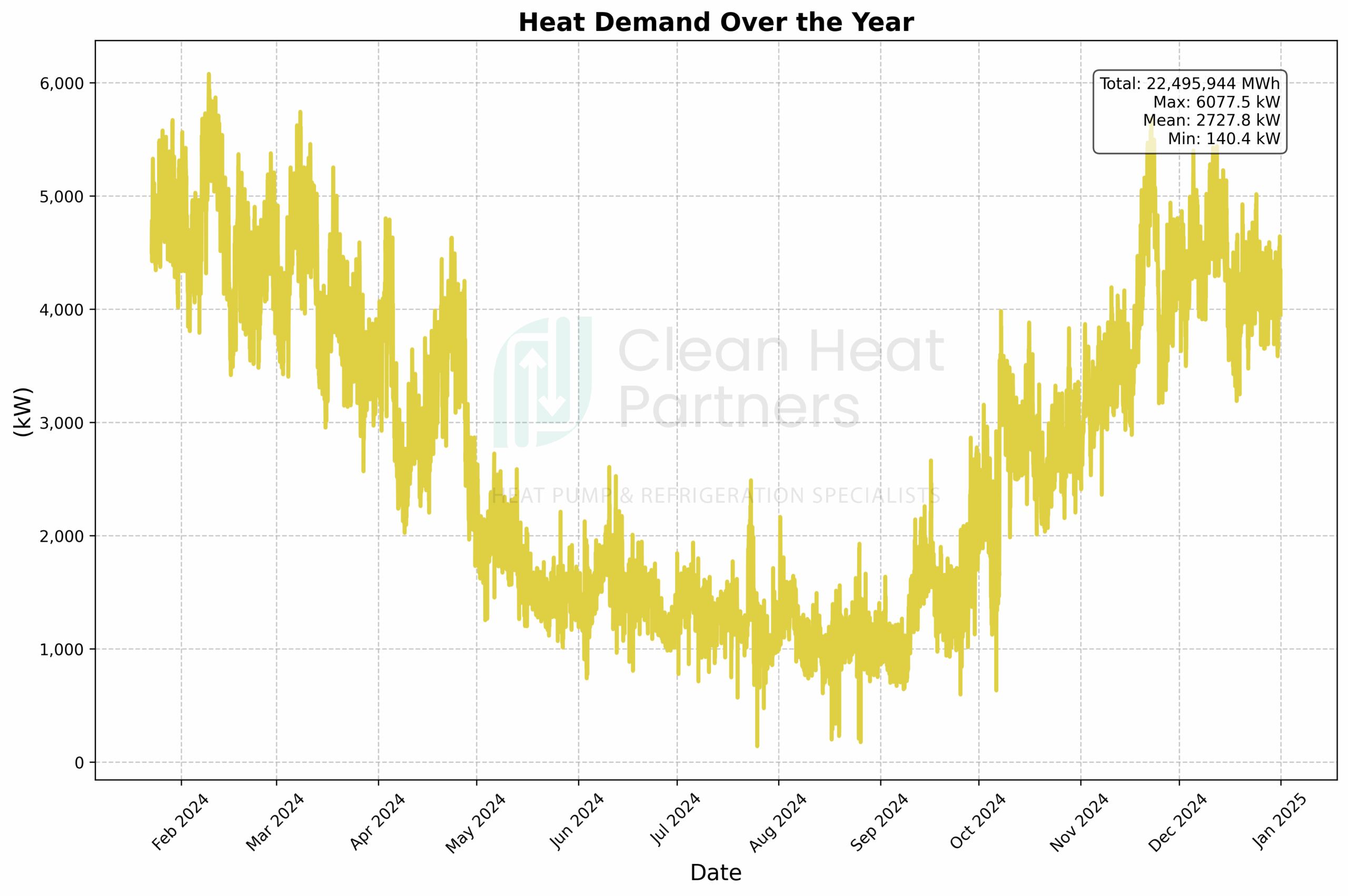

The case study simulates a full year of operation for a district‑heating system that supplies roughly 22,000 MWh of heat annually. A large‑scale heat pump provides most of the heat, supported by an electric boiler and a 2,000 m³ thermal‑storage tank.

System Configuration:

- Max demand: 6 MW / approximately 22,000 MWh per year

- Heat pump capacity: Approximately 5 MW

- Electrical boiler capacity: 10 MW

- Thermal storage: 2000 m³

- Electricity spot prices: 2024 Nord Pool DK2

- Baseline: The system simply follows the heat demand hour by hour without knowledge of future prices or temperatures.

- 1-Day Horizon: Each day the optimiser receives 24 hours of forecast data and optimises accordingly.

- 3-Day Horizon: The optimiser looks ahead three days, giving it more flexibility in planning when to charge or discharge the storage tank.

- 7-Day Horizon: The optimiser plans a full week ahead, enabling longer‑term shifting of heat production to coincide with low electricity prices and high COP periods.

In all forecast‑based cases, perfect forecasts are assumed in order to isolate the value of foresight from that of prediction accuracy.

Results

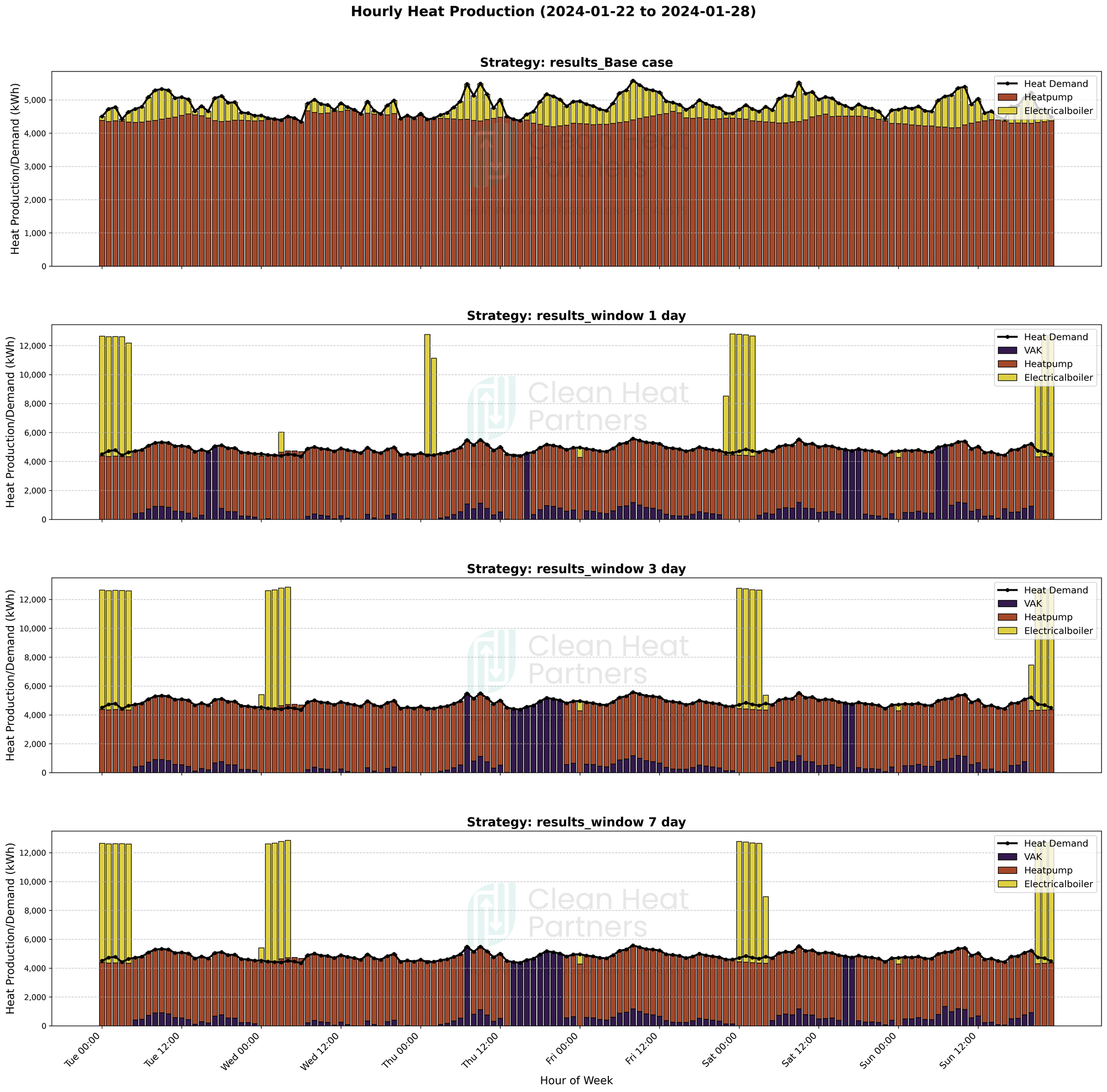

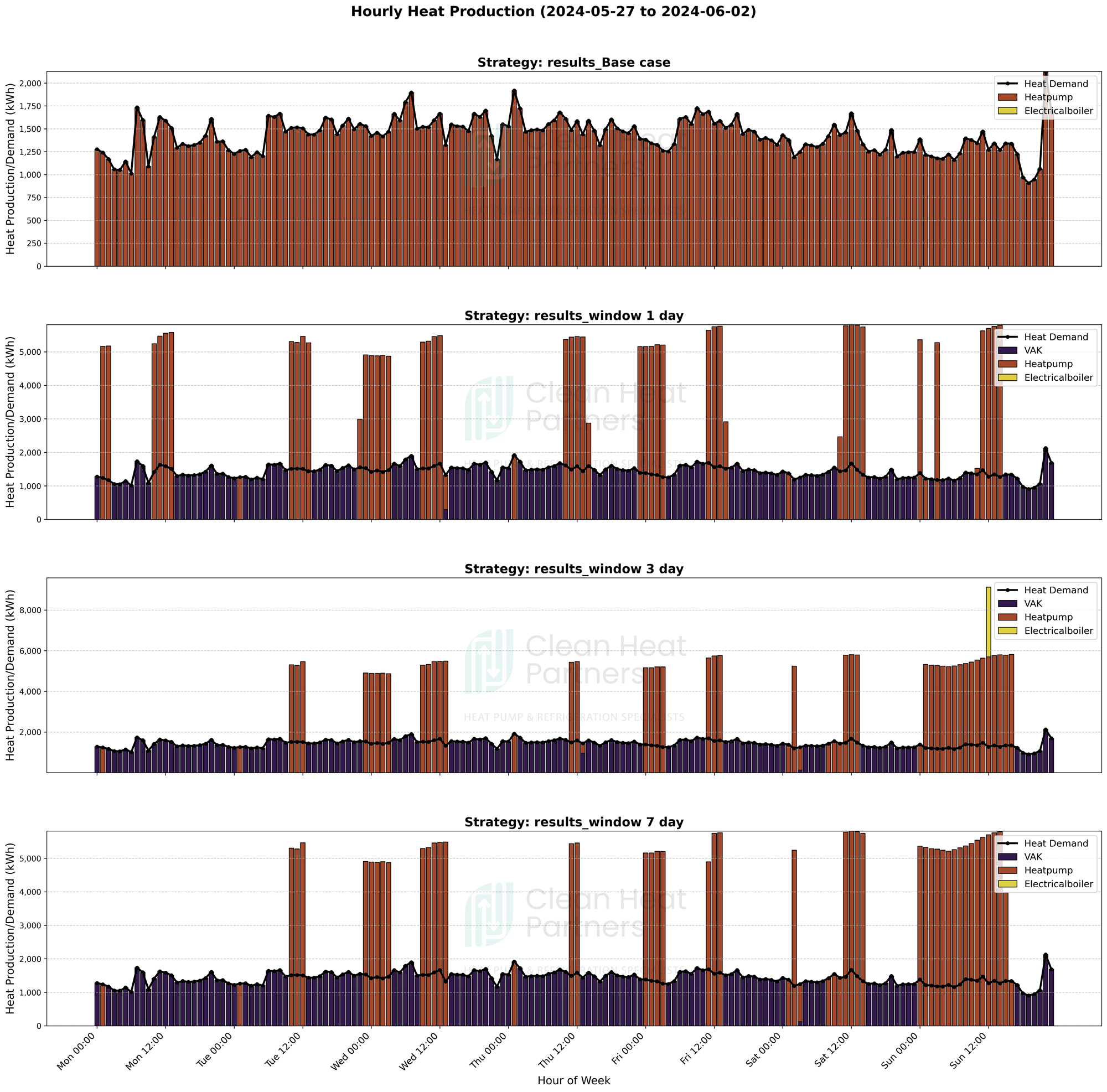

The simulations reveal substantial differences in operational strategy and cost depending on the forecast horizon.

The baseline strategy, which operates purely reactively, yields the highest annual electricity costs. It cannot exploit low‑price periods or prepare for expensive hours ahead. The thermal‑storage tank is not utilised, and the heat pump must run during high‑price periods or when its COP is poor.

The 1‑day forecast strategy already improves performance markedly. With just a day’s look‑ahead, the system can shift production to cheaper hours and prepare for forthcoming demand peaks, reducing both cost and peak‑load exposure.

With a 3‑day horizon, the optimiser gains further planning capacity. It can exploit price troughs, avoid expensive spikes and manage the thermal storage more intelligently. This yields noticeably lower costs and smoother operation each week.

The 7‑day horizon delivers performance similar to the 3‑day case, highlighting the diminishing marginal value of longer forecasts.

Key Findings

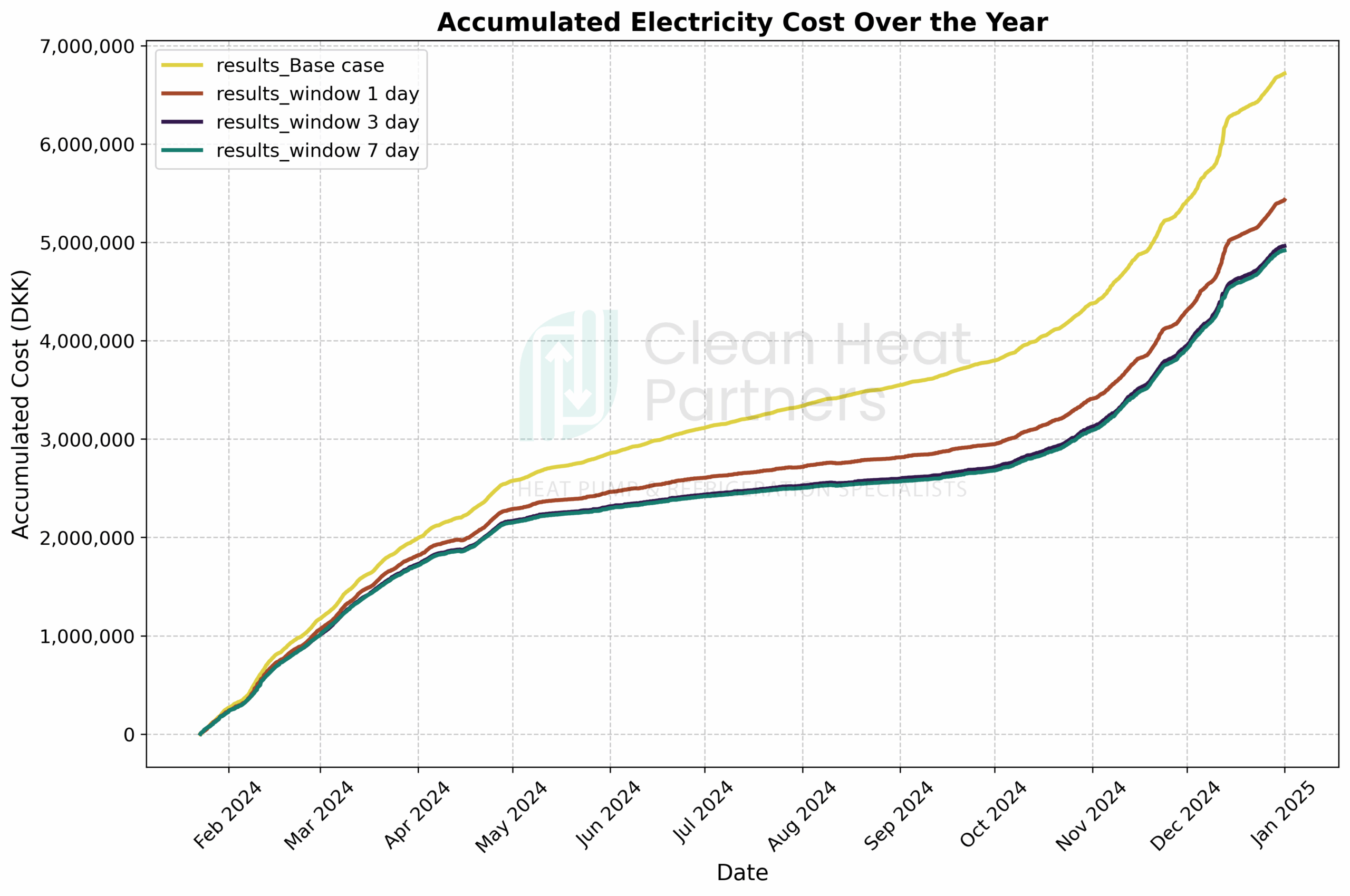

- The baseline approach is easy to implement but fails to exploit price or weather dynamics, leading to high operating costs.

- Even a 1‑day forecast enables improved control that cuts annual costs by roughly 20% compared with the base case.

- Extending the forecast horizon to three or seven days allows more optimal use of the thermal tank and ensures that the heat pump produces at the lowest DKK/MWh. Compared with the base case, annual costs are reduced by about 27%.

- Ambient‑temperature forecasting is crucial, as the heat pump’s COP varies significantly with outdoor conditions. Poor temperature estimates lead to sub‑optimal scheduling and increased energy use.

- While longer horizons generally perform better, they depend on accurate data. In practice the 3‑ and 7‑day horizons with perfect foresight deliver equivalent results.

Conclusion

This analysis clearly shows that forward‑looking control strategies, even with just one day of foresight, can materially improve the economic and technical performance of heat pumps in district heating. Using forecasts of electricity spot prices, heat demand and ambient temperature enables smarter operation, better use of thermal storage and lower electricity bills.

For utilities operating in volatile electricity markets or under time‑varying grid tariffs, integrating forecasting and rolling optimisation into daily operation offers substantial economic gains. The benefits increase with longer forecast windows, but only if the forecasts themselves are reliable.

Contact Clean Heat Partners at contact@cleanheatpartners.com.